Hangar Doors Sliding

Top Mounted Hangar doors

Top-hangar system designed for doors in top-fix and wallmount applications. The enclosed track design allows for a more secure system as the wheels cannot jump off the track. C4G can be used for a variety of door weights and applications. Ideal for heavy industrial applications including sheds and factories.

Heavy automatic hangar door can horizontally move between the top hung and bottom guide tracks. There are single, double and multi panels, which can be installed indoor or outdoor according to the actual surroundings. Hangar Door has various forms, specifications and panels.

Box track or Framed track is a top hung system, where the track is mounted over an opening. Door panels are outfitted with hanger assemblies that ride in the enclosed track. The track is attached to the building by brackets. These brackets give the track stability and strength and prevent the enclosed track from opening up over time. The weight of the door is supported only by the track system. A bottom guide/roller is used to stabilize the bottom of the door.

The sliding hangar doors are an economical solution for applications needing large, or even super-wide, doors. These doors are most suitable for oversized openings. The structures are constructed from steel channel and cold formed structural members. The features are as follows.

Bottom Rolling Hangar Doors

Hangar doors are highly recommended to install where there is no headroom and side clearances are permitted. They are either unidirectional or bi-parting with each door section top and bottom guided. If there is any pre-engineered facility, bottom rolling hangar doors make an ideal application because their heavy weight is carried out not by the building structure, but by a bottom rail. Designed to prevent indoors from all kinds of system and resist wind load, hangar doors are the most sought after in the market.

Personal experience has taught us that bottom rolling hangar doors are best suited for very large applications, as in single-aisle passenger jets and larger. These hangars are routinely so tall that a lifted-type door is absolutely not an option because of shear weight (bottom rolling doors weigh many tons per unit, far beyond the ability of hydraulics actuators to lift).Bottom rolling doors are low maintenance, particularly if they are an unpowered unit since there is little that can go wrong with this type of doors. Powered bottom rolling doors are probably the simplest of powered or assisted units with a large electric motor powering the drive wheel by use of simple direct chain drive.

-

Track sections are cold rolled from high grade galvanised or steel strip and are supplied in four sizes in standard lengths

-

Support brackets, designed for side or top fixings and for single or double track runs

-

Continuous runs of track are formed by butt-joining several lengths, using a track support bracket and welded bracket at each joint

-

Door hangers are in various designs to suit door construction. Hangers have grease packed ball bearings and alloy wheels to ensure long life and smooth running

-

Vertical adjustment is incorporated in the hanger body, avoiding the need to drill the door

-

Wicket door for easy access may be incorporated into a sliding door

-

Designed to accommodate for different industrial building designs, doors can slide to one or both sides

-

At each end, a track stopper is placed to absorb any impact and to hold the door in the open or closed position

-

Additional guides at the bottom prevent the door from oscillation

-

Interlocking facility between two doors

-

Doors can be constructed with vertical EPDM rubber seal to prevent dust and provide complete sealing

-

The C4G sliding door gear range is designed for continuous hard wearing use with sliding doors up to 3000Kgs

-

A total safety system, automatic sliding doors are designed to meet all operational & safety needs

-

Unlimited widths for manually operated ‘push along’ doors

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

Quick release disengaging mechanism inside sliding doors enables changeover to manual operation in case of power failure

-

These sliding doors can be locked in open or closed position

-

Control to stop anytime while garage door is moving

-

Single or multiple door leaf, sliding hangar doors are available in any required size

-

Sliding hangar doors can sustain extreme weather conditions and can provide excellent insulation

-

Sliding hangar doors provide the best alternative for large-scale door locations, requiring high-quality heat and noise insulation

-

Their rigid frame construction makes automated sliding doors ideal for large-scale exterior door locations

-

All gearbox and motor system are specially chosen for maximum efficiency. In addition, specially designed side drum and folding system provide extra safety and speed

| Mounting Location | |

| Technical Specification | Description |

| Product | Motorized Sliding Doors |

| Door Type | Single side / Bi-parting Type |

| Door Mounting | On Top Track Mechanism |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Mounting Location | |

| Opening Direction | Horizontal |

| Mounting Location | Inside/Outside |

| Opening Direction | Horizontal |

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

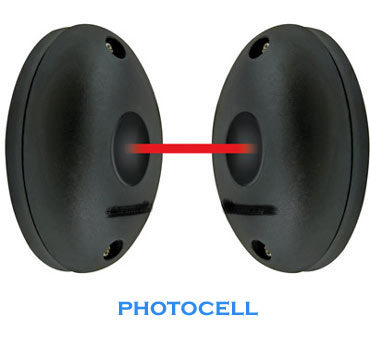

Photosells

Push Button

Remotes

Computer

Flashing light