Motorised Swing Gates

Swing gates typically travel a 90 degree arc between their open and closed positions. Swing gates can consist of a single leaf or double leafs and can be in-swinging or out-swinging. C4G has created an innovative system to incorporate an automated gate into any type of masonry column. Our inner column posts hold the weight of the gate and transfer the weight to the concrete foundations rather than the stonework. We can also hang our gates on stand alone metal posts. We build the posts to suit the project including our custom stand alone posts with a cast iron & aluminum cap and base for a beautiful finished look.

Swing gates are commonly used in residential, commercial & Industrial applications because of their low cost and ease of installation. Because swing gates travel over a large arc, space must be available to allow vehicles approaching the gate to remain clear while the gate opens or closes. Swing gate openers are electric arms that move in and out of the main opener body. This is attached both to the gatepost and part way out on the gate itself. When the remote is pressed the arm moves, so swinging the gate on its hinges to an open or closed position. The swinging arc of the gate also requires additional safety considerations to prevent people or vehicles from being hit or trapped by the moving gate.

Underground Swing Gate Automation

The C4G Underground automation system for swing gates is a geared motor. It is designed for underground installation and therefore does not alter the appearance of the gate itself. The foundation box of the automation system comes ready to take an operator. The C4G electromechanical operator is irreversible, so it ensures a mechanical stop and eliminates the need to install an electric lock for a gate up to 2 metres long.

In case of an emergency, manual operation is assured by a special lever release system with a customised key, accessible from both sides. The C4G model design includes a casing to house automated systems for gates of up to 1000kg per leaf, making installation simple. The foundation box is galvanized coating and is highly resistant to atmospheric agents, absolute weather-proofing, operators.

Overground Swing Gate Automation (Articulated Arm)

The C4G external automation with articulated arms automates residential swing gates with leaves of up to 3m in length. It consists of an irreversible electro-mechanical operator with guard and an articulated-arm activation system to be fitted to the gate with the appropriate accessories. The irreversible system ensures the automatic swing gate is mechanically locked when the motor is not operating. No locks need to be installed for leaves up to 1.8 metres in length. A manual release makes it possible to move the gate in the event of a power-cut or fault.

Heavy Duty Overground Swing Gate Automation (Hydraulic Arm)

The Heavy duty automation system for swing gates is a hydraulic unit comprising an electric pump and a hydraulic piston which moves the gate leaf. In case of an emergency, a customised release key makes it possible to operate the gate manually.

For high levels of use such as entrances/exits for apartments or office blocks, we would recommend that you fit a timer to open gates during busy periods of traffic.

-

Trackless design means unlimited overhead clearance and no special drains below

-

Automatic swing gates can work even under the most difficult conditions

-

Gates are specially designed with top and bottom pivot mechanism

-

Dust proof operating mechanism increases the life of our gates

-

Our Gates leafs are free from sagging/bending

-

Unit arrives ready to bolt down and turn on, virtually no field assembly required

-

Aesthetically pleasing Anti-climb configuration available

-

Spring loaded hinges assures gate will be closed when not in use

-

Single or Dual-Panel design allows for easy loading/unloading operation

-

Slide design takes up less floor space than swing design

-

Suits gates up to a weight of 300 to 1800kgs

-

Anti crushing safety device built in to the system

-

Slow down mode when closing to prevent slamming of the gate – reducing noise

-

Easy to operate manual release in case of a power black out

-

Easy to operate manual release in case of a power black out

-

Electro-mechanical swing gate operator designed for medium to intensive use

-

Electro-hydraulic swing gate operator designed for medium to very intensive use

-

Various industrial gate designs available to suit clients choice

-

Control to stop anytime while gate is moving

-

Sand blasting, Hot deep galvanizing process, painting can be provided

PRODUCT |

Automatic Swing Gates |

||

GATE DIMENSION |

|||

| Width Min./Max. | Single Leaf : 1200/3800mm Double Leaf :2400/7500mm |

||

| Height Min./Max. | 1200/2300mm Larger Dimension on request |

||

| Max. Number of Leaves | Single Leaf:1 Nos Double Leaf:2 Nos |

||

| Mounting Location | Inside/ Pillar center | ||

| Mounting Surface | Columns : RCC | ||

GATE STRUCTURE |

|||

| Pattern | Standard Mild Steel and Stainless Steel Tubular pattern | ||

| Internal member | Heavy Duty Vertical Box sections (or Customized design available on request) |

||

| Outer Frame | Heavy Duty tubular box section (or Customized design available on request) |

||

| Full height Column | Heavy Duty Box Section (or Customized design available on request) |

||

| Hinges | High precision top & bottom pivoted hinges with ball bearing / heavy duty hinges | ||

PATTERNS/DESIGNS |

|||

| Other available gate material | Stainless Steel, Hot dip Galvanized Steel, Cast Iron Steel, Mild Steel |

||

| Sheets | M.S/GI/Perforated /Aluminium sheets Polycarbonate / Acrylic / PVC Sheet/Glass/Wood/WPC Wood/Fundermax panels |

||

| Ornamental Designs | On Request or as per client or architect design. | ||

| Options Available | Spikes as per requirement Wicket gate/Side Gates in the similar pattern as the main gate Any type of Customized Design can be made on request. |

||

FINISH |

|||

| Surface Finish | Surface preparation:-Sand Blasting Standard: Primer Finish Optional: Enamel Painting/Duco/PU painting/ Powder coating/ Hot deep Galvanising |

||

DETAILS FOR AUTOMATION SYSTEM |

|||

| Drive Unit | Motor arm or Underground motor selection done on space availability & frequency of operation. Single( A.C & D.C )Phase |

||

| Emergency Operation | Manual release knob | ||

| Accessories (Optional) |

|

||

| Features | Interlocking with existing boom barriers if required | ||

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

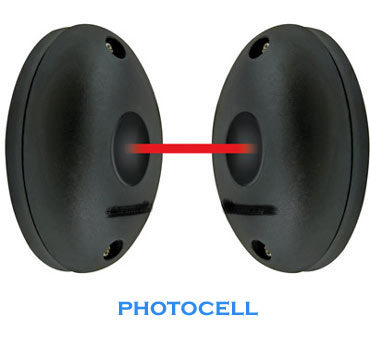

Photosells

Push Button

Remotes

Computer

Flashing light