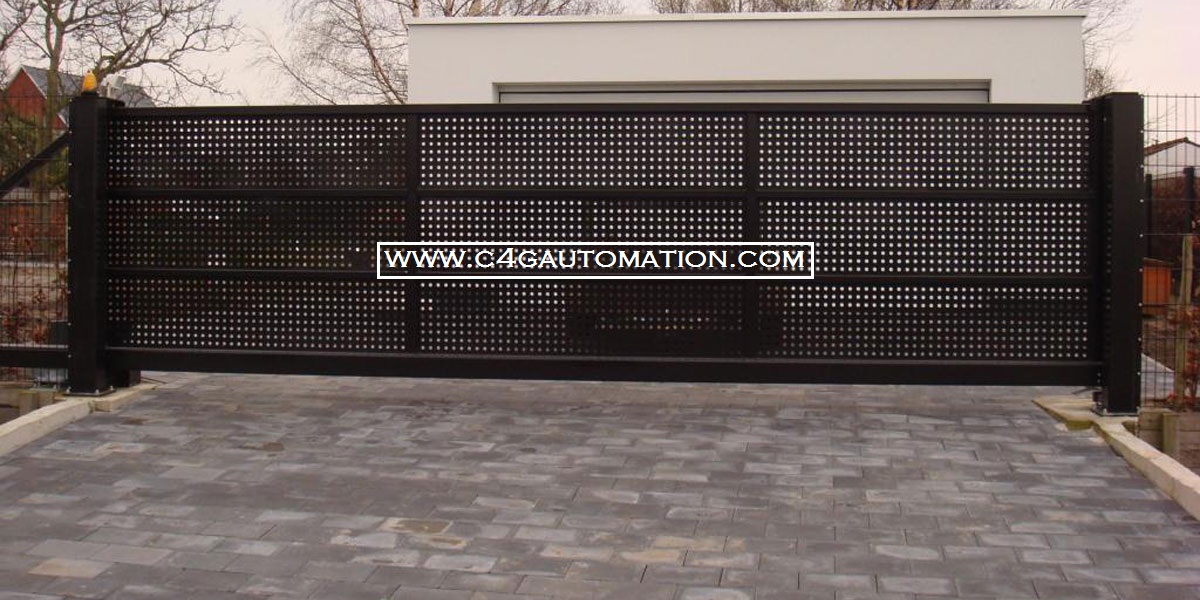

Motorised Commercial Cantilever Sliding Gates

C4G commercial cantilever sliding gates are the ideal for applications requiring automatic gate operator systems since no part of the gate comes in contact with the ground. Also, the most durable type of automatic electric gate operator for high usage in cold weather applications is sliding gate operators (as opposed to Swing Gate Operators). Proper design, fabrication, and installation of a cantilever sliding gate will reduce friction during operation and prolong the life of a gate operator. The commercial cantilever gate frame must be constructed properly to help withstand the forces of gravity and wind. Intricate diagonal bracing and trusses are strategically welded in place to help prevent gate sag.

Commercial cantilever sliding gates have commercial three phase motors with reduction gear which has power adjusted to the size of each gate. Adjustment of the cycles to within a centimetre is provide by an encoder built into the motors compensating the travel end sensors. The motor reduction unit can be disengaged easily in the event of a power cut. The drive consists of pinion gear and a chain system mounted on tensioners. The essentials of the system are invisible to the eye. C4G commercial cantilevered sliding gates protect your investment, assets and security, permanently and reliably.

-

Gates can be provided with either top or bottom guide track or in a new trackless version

-

Gates are specially designed with top and bottom pivot mechanism

-

Dust proof operating mechanism increases the life of our gates

-

Our Gates leafs are free from sagging/bending

-

Suits gates up to a weight of 1200kgs

-

Anti crushing safety device built in to the system

-

Easy to operate manual release in case of a power black out.

-

Opening / closing speed– fully programmable for slower speeds

-

Trackless design means unlimited overhead clearance and no special drains below

-

Ideal for tight spaces where there is little room to swing or slide a traditional automated gate

-

Unit arrives ready to bolt down and turn on, virtually no field assembly required

-

Electro-mechanical continuously rated overhead drive and guide track system

-

Infill can be custom designed to suit any architectural or client brief

-

Control to stop anytime while gate is moving

-

Sand blasting, Hot deep galvanizing process, painting can be provided

PRODUCT |

Motorised Telescopic Sliding Gates |

||

GATE DIMENSION |

|||

| Width Min./Max. | Single Leaf : 1200/16000mm Double Leaf :2200/32000mm |

||

| Height Min./Max. | 1000/2700mm Larger Dimension on request |

||

| Opening Direction | Horizontal | ||

| Mounting Location | Inside/ Outside | ||

| Mounting Surface | Bottom Rail: RCC Columns : RCC |

||

GATE STRUCTURE |

|||

| Outer Frame | Heavy Duty tubular box section (or Customized design available on request) |

||

| Internal vertical member | Heavy Duty Vertical Box sections (or Customized design available on request) |

||

| Bottom Rollers | European make and Indian make high performance dual pattern hangers equipped with noiseless ball bearings | ||

| Pattern | Standard Mild Steel Tubular pattern | ||

| Full height Column | Heavy Duty Box Section (or Customized design available on request) |

||

| Cantilever Track | European make imported make and Indian make Cantilever Track | ||

| Guide Rollers | Nylon Rollers with bearings both side mounted on column for support & smooth movement of gate. | ||

PATTERNS/DESIGNS |

|||

| Other available gate material | Stainless Steel, Hot dip Galvanized Steel, Mild Steel, Aluminium Steel |

||

| Sheets | M.S/GI/Perforated /Aluminium sheets Polycarbonate / Acrylic / PVC Sheet/Glass/Wood/WPC Wood/Fundermax panels |

||

| Ornamental Designs | On Request or as per client or architect design. | ||

| Options Available | Spikes as per requirement Wicket gate/Side Gates in the similar pattern as the main gate Any type of Customized Design can be made on request. |

||

FINISH |

|||

| Surface Finish | Surface preparation:-Sand Blasting Standard: Primer Finish Optional: Enamel Painting/Duco/PU painting/ Powder coating/ Hot deep Galvanising |

||

DETAILS FOR AUTOMATION SYSTEM |

|||

| Drive Unit | Imported & Indian make electromechanical drive having features such as powerful startup & thermal sensors Single( A.C & D.C )/Three Phase |

||

| Emergency Operation | Manual release knob | ||

| Accessories (Optional) |

|

||

| Features | Interlocking with existing boom barriers if required | ||

-

1

Hospitals

-

2

Pharmaceutical

-

3

Aircraft

-

4

Shipyards

-

5

Food Industries

-

6

Retail & Mall

-

7

Automobiles

-

8

Engineering

-

9

Logistics

-

10

Villa Residency

-

11

Chemical Industries

-

12

Educational Institutions

Key Switch

GSM

Biometric Reader

Access Ctrl Card

RFID

Safety Edge Sensor

Wifi

Mobile

Photosells

Push Button

Remotes

Computer

Flashing light